The DIYLaserBed is a hight adjustable bed for K40 laser cutters and clones.

Latest Updates:

05 May 2023 - RevB Built

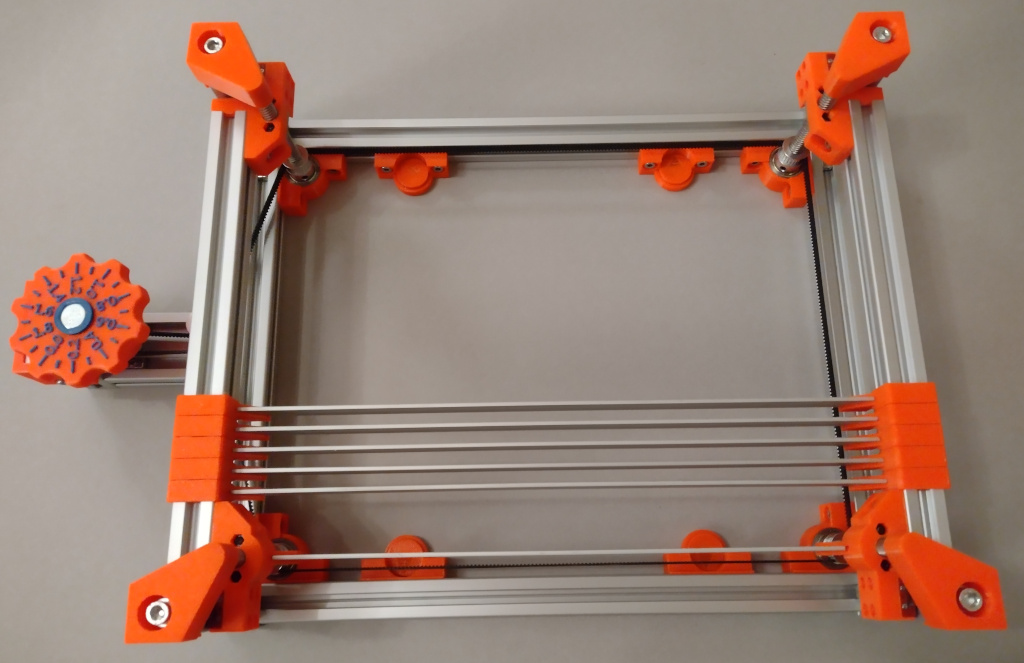

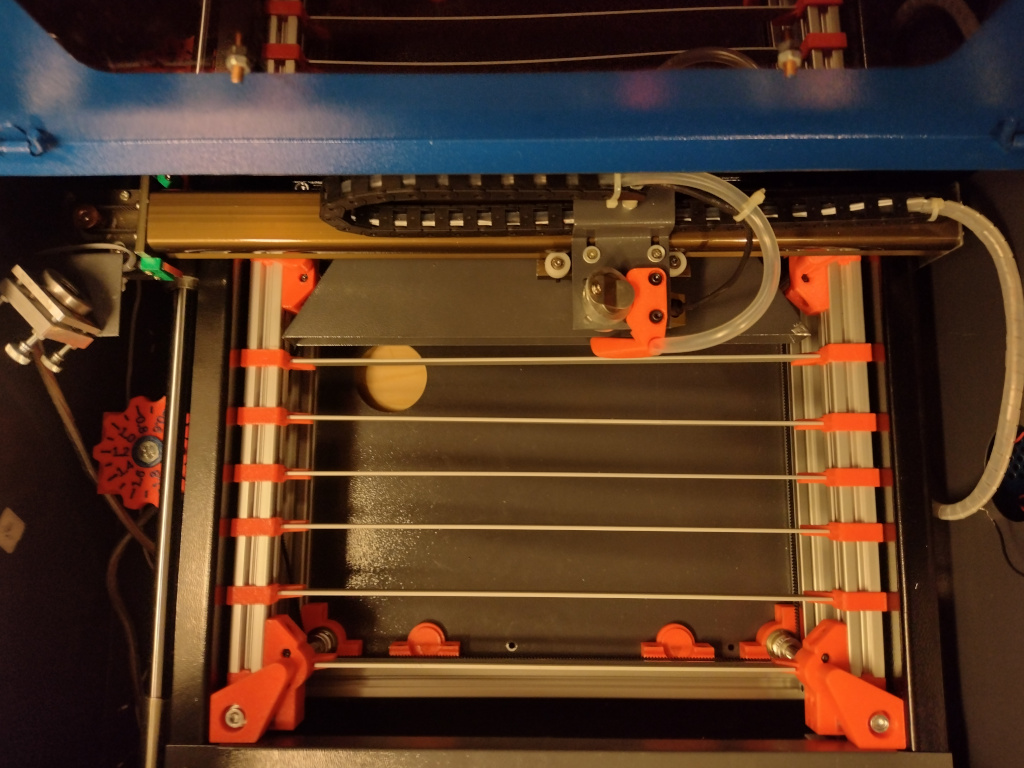

The new laser bed is assembled and built into my laser cutter.

I thought I would be able to put the laser bed together inside my K40 clone, but I ended up taking the lasser cutter apart to insert the fully assembled table. The manual crank works pretty well and I can reach everything I need in the tight space to readjust the belt, if necessary.

28 Apr 2023 - RevB Designed

I’ve desigend a new version of the laser bed. The improvements are:

- It fits better inside my K40 clone

- It’s less bulky and takes away less cutting area

- Tte bed can be lowered farther

Except for some 2mmx15mm aluminium flat sections, it reuses the non-printed parts of revA.

12 Jun 2020 - DIYLaserBed assebled

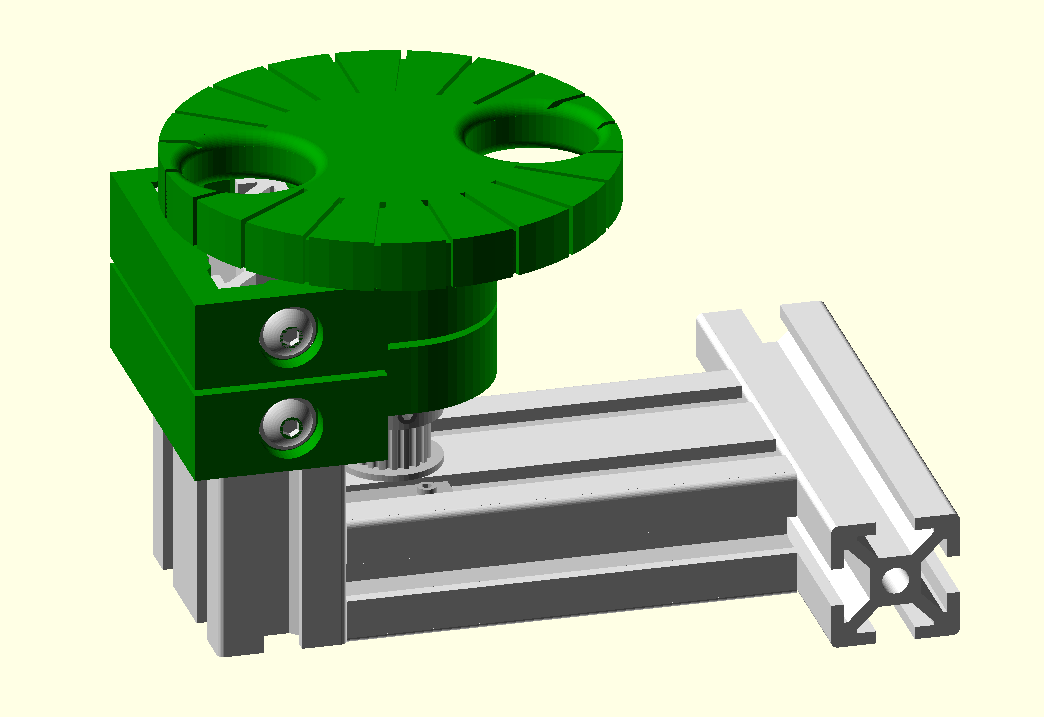

The DIYLaserBed has been assembled and it works. I’ve redesigned the crank wheel to make it fit into trhe laser cutter. This is my initial and my final design (my first multi color print).

My timing belt turned oit to be a little longer than what I had ordered, but there is still plenty of room to tighten it.

Now the whole thing needs to be reassembled inside my laser cutter.

10 Jun 2020 - Assembly started

Finally all vitamins have arrived in the mail. As I have started the assembly of the DIYLaserBed I found a number offlaws in the design:

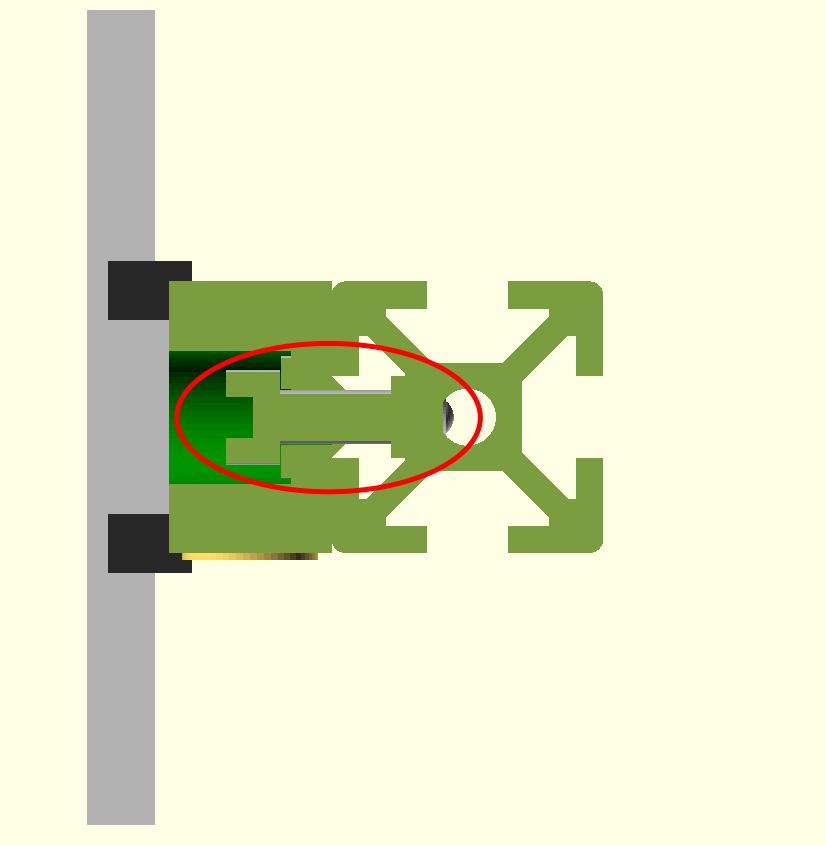

Carriage

The T-Nuts have been misplaced. Tn the construction, they actually reach into the extrusions.

For the assembly this means that shorter M4 screws are required ttan listed in the BOM.

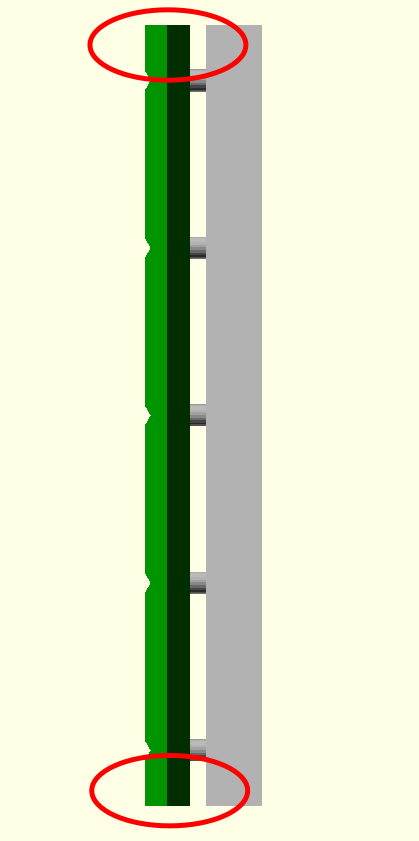

Rails

I had ordered cheap rails from China. As it turns out, the holes in the rails were not aligned as expected, therefore the holders peek out over the edge of the column extrusions.

The rail holders have now been shortened to compensate for the offset of the holes.

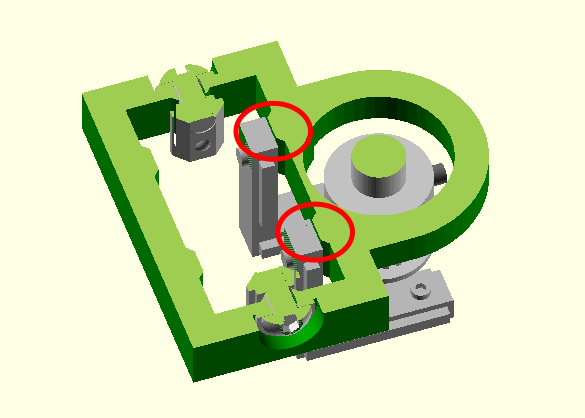

Crank Bearing holder

The lower bearing holder of the crank does not fit right because the L-brackest are in the way.

The inner profile of the holder had to be adjusted.

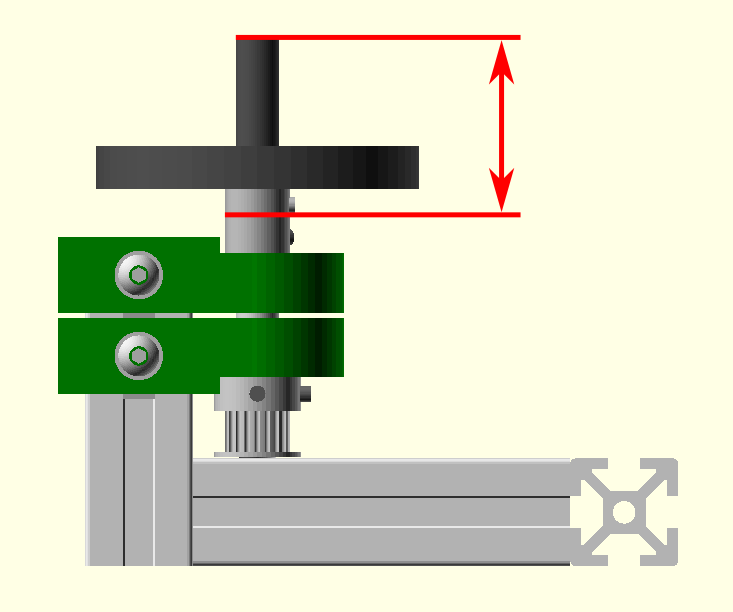

Crank

The biggest design flaw of them all is the crank itself. It is simply too high to fit into the laser cutter’s enclosure. The stepper motor of the X-axis will crash against it.

I’ve replaced the shaft with a M8 hex screw and designed a flat crank that fits on the screw head.

All of these design problems have been fixed in the repository.

01 Jun 2020 - New Printer

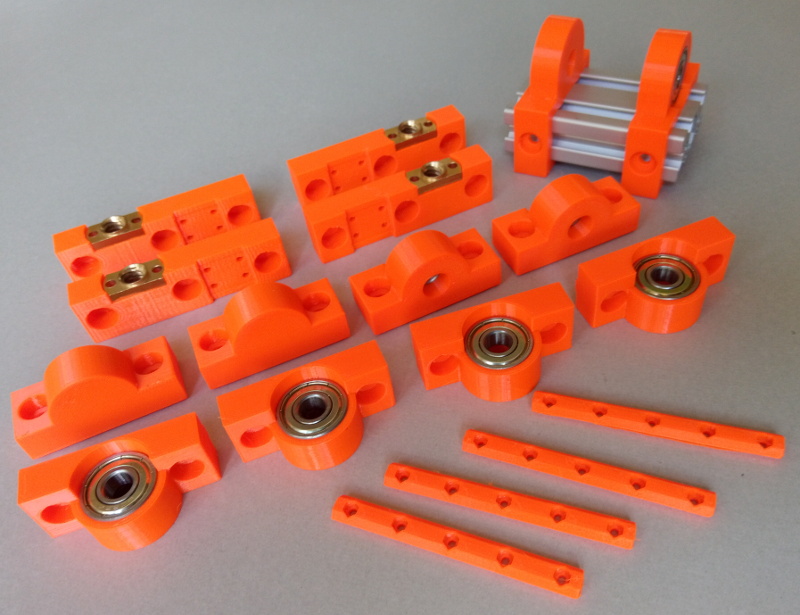

As it turns out, I didn’t need to make my design more printer friendly. I just needed to buy a decent printer.

My printing struggles are over. My new printer produces the DIYLaserBed parts just fine.

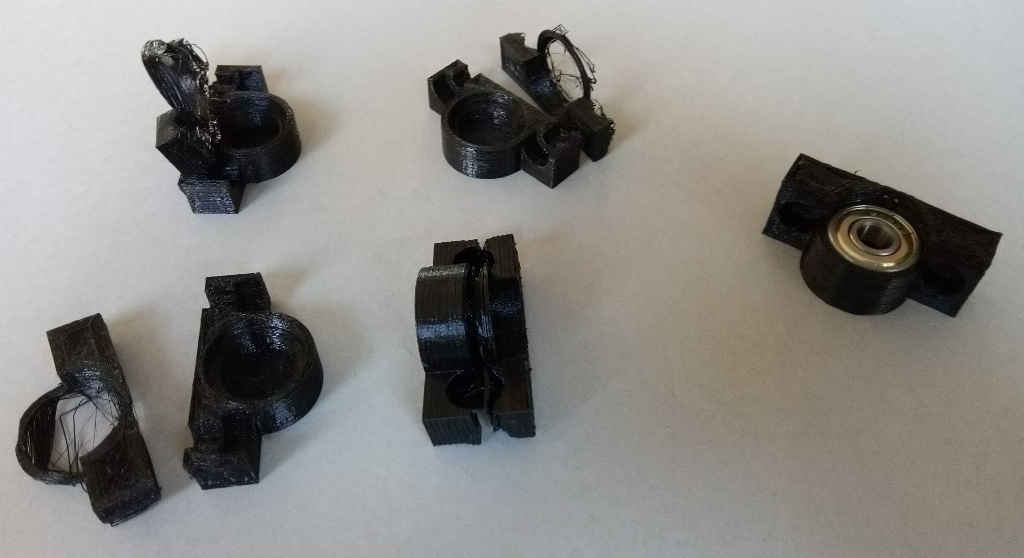

31 Mar 2020 - Printing Struggles

While waiting for some missing vitamins to arrive by mail, I’ve been working on the 3D prints. For many 3D printers these parts are probably no issue, but my Prusa clone has struggles with my design. For example, the lower bearing hoder has a couple couple of layers low print volume. At these layers, the filament does not adhere well.

I think I need to make this design more printer fiendly.

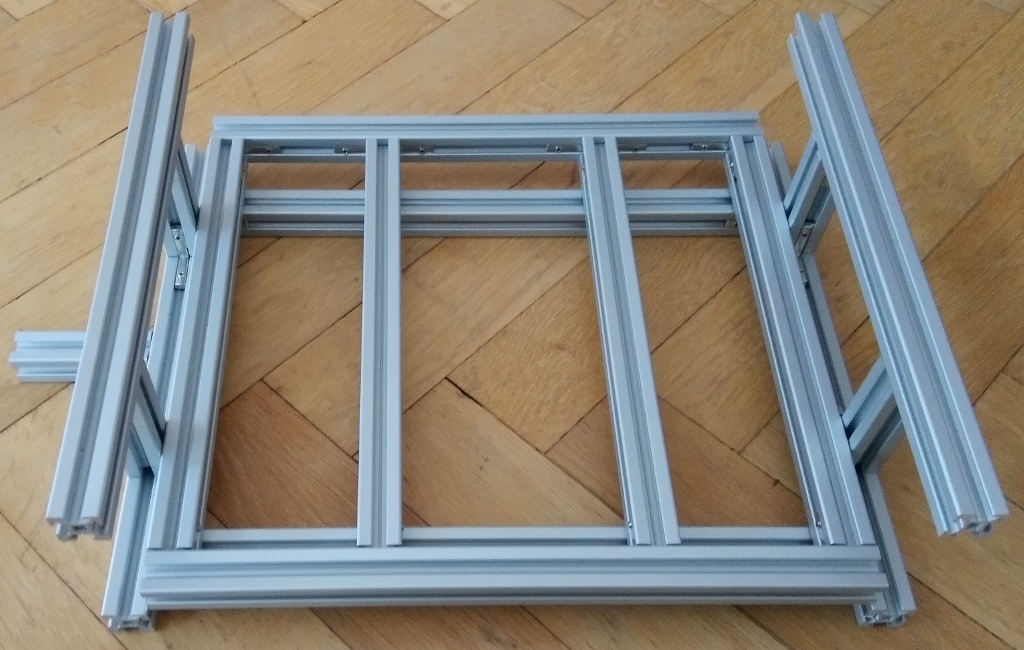

06 Mar 2020 - Aluminium Extrusions Have Arrived

The aluminium extrusions have arrived. Weiting for the rest of the vitamins.

26 Feb 2020 - Project Started

This is a laserbed design for K40 laser cutter clones. It is supposed to be easy to rebuild, as it only uses common mechanical components and a few simple 3D-printed parts.