This project has been created to capture everything related to my attempt of building an air vent for my CO2 Laser cutter.

Latest Updates:

22 Jun 2020 - Vent assembled

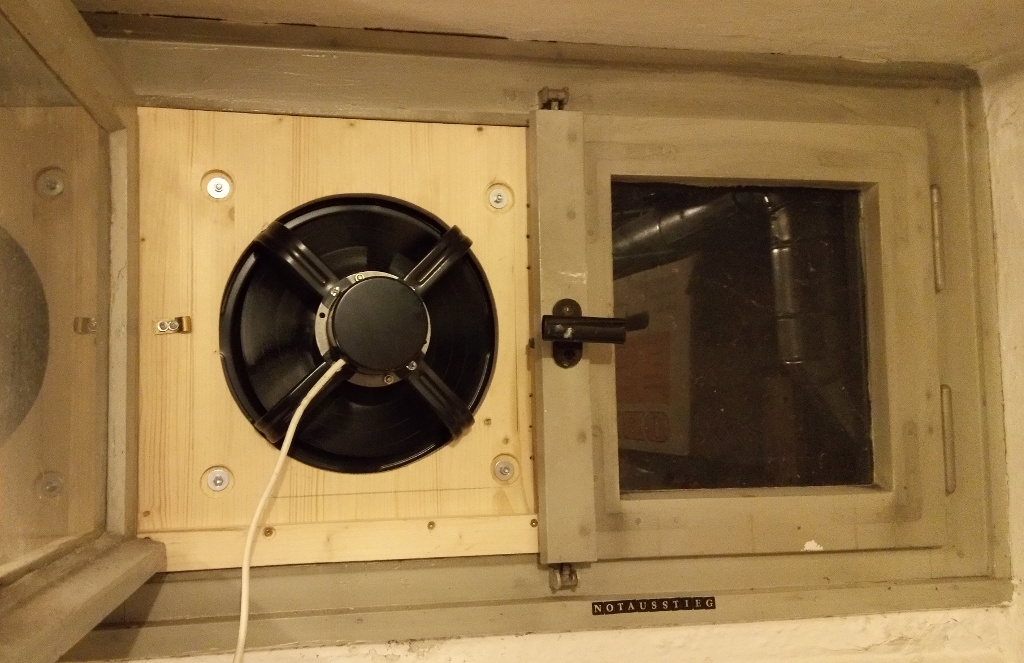

After nearly 80 hours of printing, the vent cover has been ready for assembly. Initially I had mounted the printed cover on the wooden box that I fad built before. The airflow was better but still not great. The air was just circulation in the space between the cover and the fan. Then I built a narrower frame to move the cover closer to the fan. I also printed four more fins for the inside of the frame, to reduce the air circulation even more

The airflow has improved, but it could be better if it had more fins that were located closer to the blades of the fan.

But for now this is my working solution. Unfortunately, my new frame does not allow me to shut the right side window anymore

If I do a redesign of the vent cover, I’ll leave out the wooden frame and make a round fully printed shape that fits very closely around the fan.

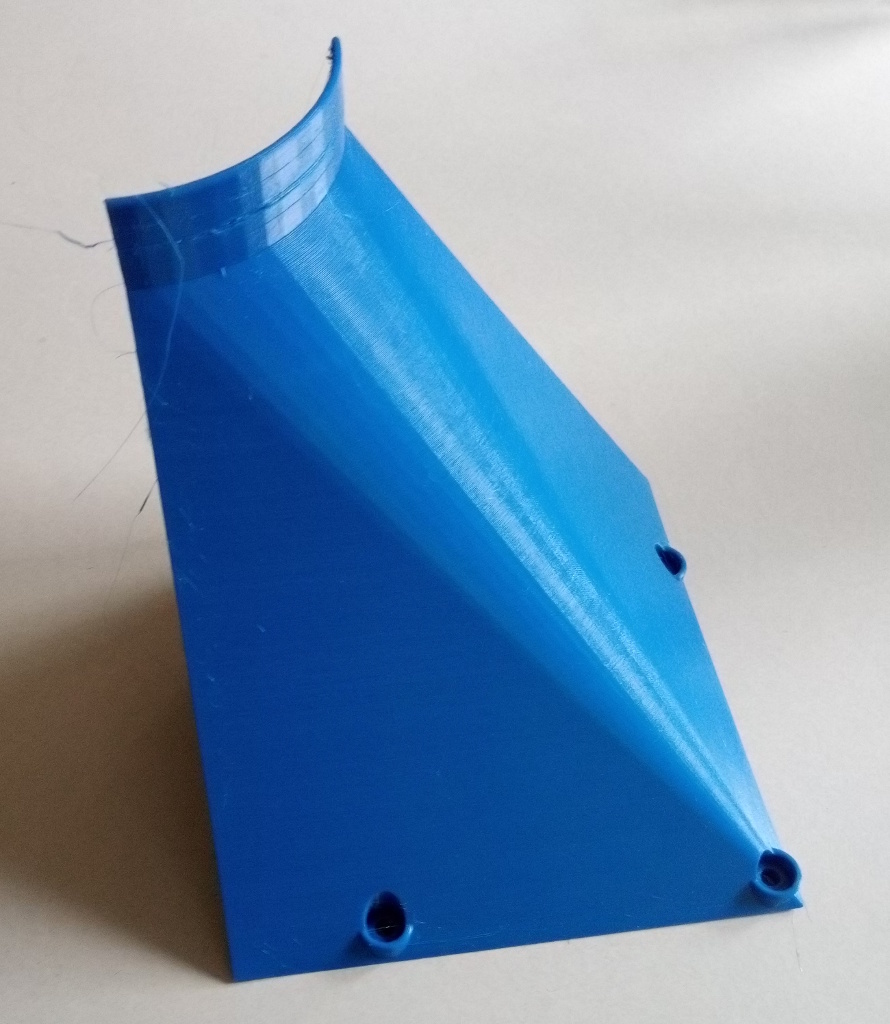

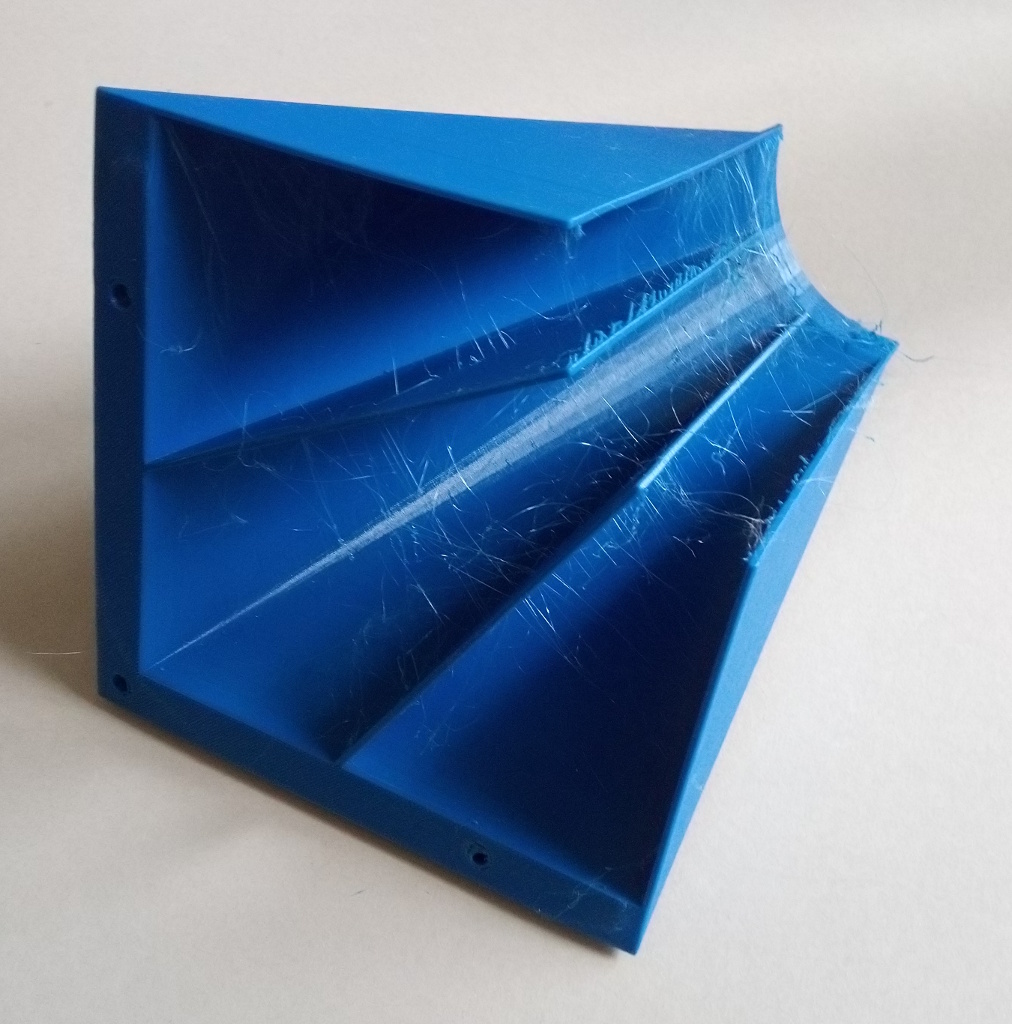

15 Jun 2020 - First corner printed

The first corner of the fan cover is finished. It took over 20 hours to print.

The print is a bit stringy, the fins are slightly warped and when it came to the hose connector, my printer was acting up. But overall, the print is usable. On to the next one!

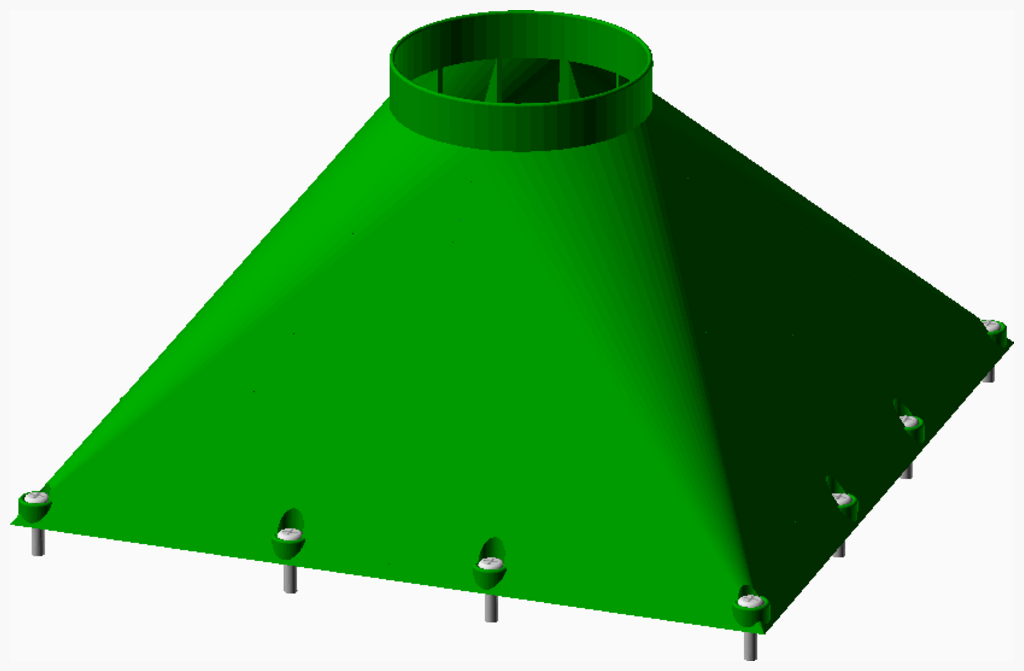

14 Jun 2020 - Fan cover designed

The new design of my fan cover is done.

I’ll have to print it in four parts. Each part will take a little less than 20 hours to print.

12 Jun 2020 - Project started

When I needed a venting solution for my CO2 laser cutter, I bought myself an exhaust fan from eBay and build a wooden frame around it, that would fit in the window of my basement.

Next I build a box shaped enclosure around the fan opening, cut a hole in the middle of the front sheet and connected the exhaust hose of the laser cutter to it. This kind of worked, but the air flow wasn’t great.

Than I came up with the idea that I couls share the window fan between the laser cutters exhaust and its water cooling system. I rearranged the hose inlet and added sokle radiators.

While thts water cooling systen didn’t leak out any water, it leaked in a lot of air. So I desided to make my cooling system more compact and reduce the number of couplings to a minimum (see [DIYWaterChiller).

So my next task is to redesign the fans enclosure to only fit the exhaust hose, but this time with a better airflow. Since my local community wood workshop is closed due to corona orders, I plan to use 3D printed parts. And this repository is the storage space for my designs.