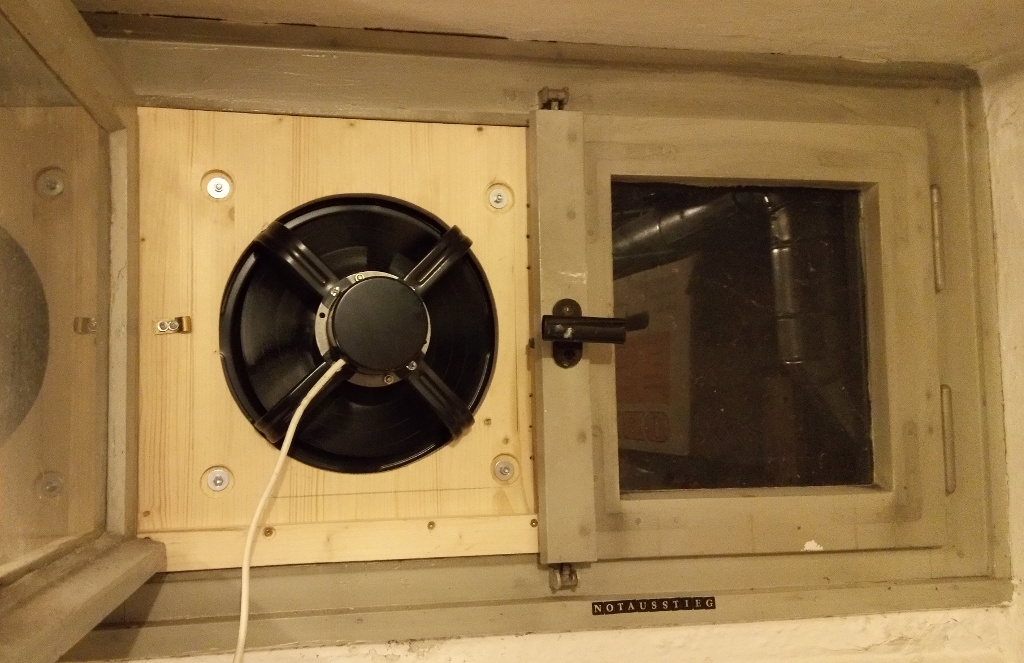

When I needed a venting solution for my CO2 laser cutter, I bought myself an exhaust fan from eBay and build a wooden frame around it, that would fit in the window of my basement.

Next I build a box shaped enclosure around the fan opening, cut a hole in the middle of the front sheet and connected the exhaust hose of the laser cutter to it. This kind of worked, but the air flow wasn’t great.

Than I came up with the idea that I couls share the window fan between the laser cutters exhaust and its water cooling system. I rearranged the hose inlet and added sokle radiators.

While thts water cooling systen didn’t leak out any water, it leaked in a lot of air. So I desided to make my cooling system more compact and reduce the number of couplings to a minimum (see [DIYWaterChiller).

So my next task is to redesign the fans enclosure to only fit the exhaust hose, but this time with a better airflow. Since my local community wood workshop is closed due to corona orders, I plan to use 3D printed parts. And this repository is the storage space for my designs.